DCSC-W-5 fume absorbers are designed for local extraction of aerosols and dust particles formed during welding, cleaning, grinding of metals, as well as similar types of processing of various materials.

Principle of operation

The principle of operation of filtered units is based on local capture of polluted air, mechanical purification of air from harmful substances, and return of the clean air to the production area.

Air recirculation allows to reduce energy consumption for general ventilation of premise, maintenance of the filter itself and protects the working personnel from the effects of harmful substances released during different processes and operations.

Working conditions

DCSC-W-5 filters are designed for continuous indoor work with following conditions:

- Environmental temperature from +5 to +45 °С;

- Relative humidity not more than 80% at +25 °С;

- Airflow temperature not more than +80 ºС;

- Air must be inexplosive and must not contain aggressive steam and gases, sticky and fibrous dust and prone to decay and self-combustion material and particles.

Industries and applications

- Welding processes

- Dust extraction

| DCSC-W-5 | DCSC-W-5-K | DCSC-W-5-F | DCSC-W-5-F-K | |

|---|---|---|---|---|

| Max airflow, m³/h | ||||

| Power consumption of the filter, kW | ||||

| Filter supply voltage, V / Hz / Phase | ||||

| Motor power, kW | ||||

| Max. compressed air consumption, L/min. free air: - factory setting (1 pulse/min.) - manual setting (up to 3 pulse/min.) | 135 |

|||

| Pressure of the supplied compressed air (working) MPa(bar) | (5.0 - 5.5) | (5.0 - 5.5) | ||

| Filteration class (DIN EN 779-93) Filteration class (DIN EN 60335-2-69 ) | M |

|||

| Noise level, dBA | ||||

| Diameter of the inlet for the pipe, mm | ||||

| Overall dimensions, mm | ||||

| Filter weight, kg | ||||

| IP rating | ||||

| Mode of operation | ||||

| Compressor type | ||||

Advantages and design features

● High performance – 1200 m³/h with low power consumption – 1.1kW;

● Compact body;

● Low noise level – 66dBA;

● Vertical quick-release cartridge with high filtration class-F9;

● Programmable logic control system for cleaning the cartridge with ΔP-function, which extends the service life of the filter element and reduces the consumption of energy and usage of compressed air;

● Light and sound signaling when the cartridge needs to be replaced;

● Simple system of pressing and fixing the cartridges for easy maintenance of the filter;

● Built-in oil-free compressor (in DCSC-W-5-K models);

● Two-stage spark protection, reducing the risk of fire;

● Outlet of cleaned air upward;

● Possibility of having filter control buttons on the extraction hood(optional).

Design

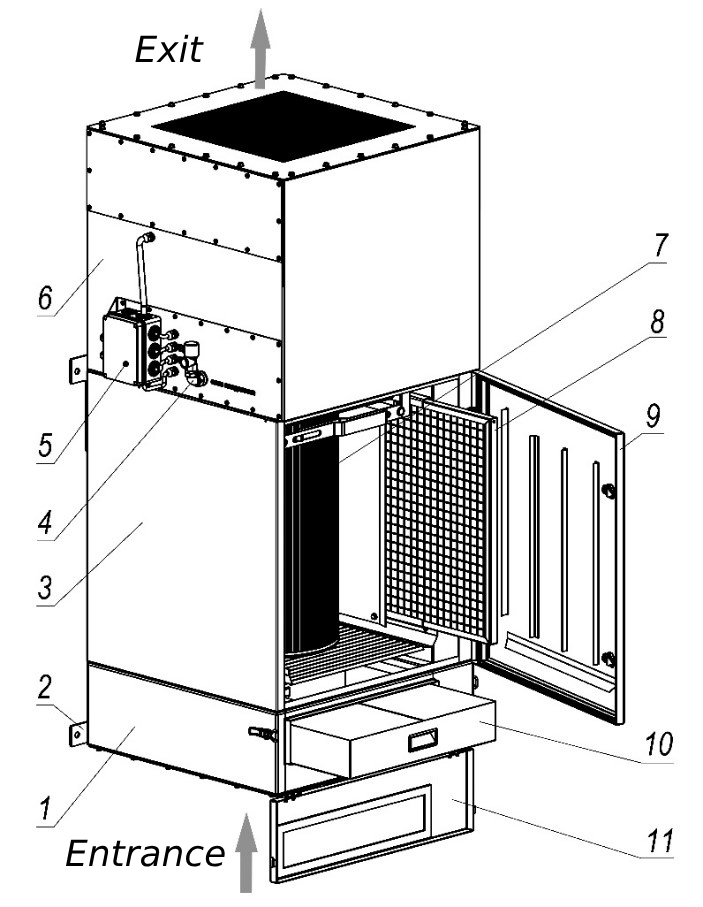

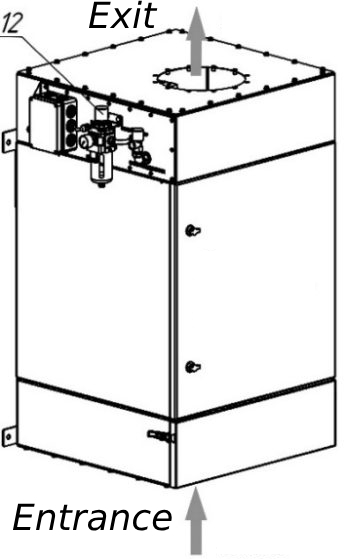

Design of models with in-built fan (DCA-W-42-F4 as a sample)

Picture 2

– Picture 1 – built-in fan without compressor;

– Picture 2 – built-in compressor without a fan.

1. suction chamber;

2. lugs for wall mount;

3. filter module body;

4. safety valve;

5. terminal block;

6. fan body;

7. cartridge;

8. prefilter;

9. filter door;

10. dustbin;

11. suction chamber door;

12. oil-water separator

Delivery set:

- in-built fan;

- in-built air compressor (models DCSC-W-F-K);

- oil-water separator with pressure valve and manometer (models DCSC-W-5-F);

- vertical cartridge with splitter;

- control panel with ΔP-function, visible and audible, and transformer for BEA extraction arms with lighting;

- wiring cable with earth connection plug.

Options:

- mesh prefilter.