SovPlym manufactures a wide range of air-filtration equipment for soldering, manual and robotic welding, grinding, thermal cutting, laser marking and engraving.

The product range includes extraction arms of different diameters, filter-ventilation units of several cleaning types, fans of various productivity, as well as accompanying automation devices, spares and accessories.

Our equipment can solve all scope of possible tasks: from minor local dust removal to design of overall air cleaning systems in large manufacturing premises.

Need help to get the right equipment for your project?

Our experts are ready to answer all your questions.

Application of Local Extraction Ventilation

Capturing and cleaning of contaminated air at places of its emittance.

Perfectly suits for welding and metalwork, processes with chemical reagents and bulk products.

Local extraction devices are intended for capturing pollutants at the source. Their usage provides effective seizing and removal of dust and smoke at places of their origin and concentration, thus providing clean air in working area.

SovPlym Local Exctraction Ventilation:

We manufacture all related to local exhaust ventilation products: extraction devices, dust collectors, cartridge filters, draft tables and panels, and modular downdraft tables for thermal cutting.

Our product range includes extractors of different types: mobile, stationary and wall-mounted; accumulative, self-cleaning and electrostatic; cartridges made of different materials.

Our products can effectively treat any technological process at your manufacturing site.

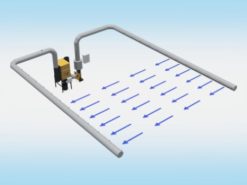

For welding of long-length and oversized items we offer filter-ventilation air-circulating systems PUSH-PULL ® and DILUTER.

Why is it important to install LEV system at the manufacturing site?

Harmful industrial processes

Welding and thermal cutting fumes and aerosols, as well as dust from stripping, shot- and sandblasting, lathe and milling works and other metalwork processes present serious hazard for health, equipment and ecology.

High business risks

Damage to employees’ health and lost productivity.

Fumes and invisible to the naked eye small particles are so hazardous because they stay in lungs and provokes chronic diseases. This results in low staff performance and frequent medical leaves.

Early equipment deterioration, possible production downtime and profit lost

Dust and aerosols get inside the machines, control consoles and other electronics. As a result, expensive equipment can be out of service that leads to profit lost. Moreover general ventilation and conditioning systems also get clogged.

Environmental pollution, fines and reputation risks

Environment is another vital issue which attracts more and more attention both of the State and citizens. Air emissions can result not only in fines and production downtime, but in reputational risks as well.

Local extraction ventilation minimizes these risks.

Increase of enterprise energy efficiency

SovPlym air cleaning systems are equipped with intelligent automation and sensors, which provide optimum equipment performance and reduce energy cost.

Automation significantly decreases risks of equipment damage and provides possibility to monitor its operating conditions. This allows to simplify service processes and its expenses.

Contacts

Arrisa Avenue, Unit #15, Office No. 303, 3rd Floor, Kolte Patil Downtown, Kharadi, Pune-411014, India