DCA-M mobile mechanical fume extraction solution is designed for capturing and purification of air contaminated by soldering, tin-plating, laser engraving and marking, resistance and arc welding processes, and also by dry, unsticking, nonfibrous dust of low concentration.

Filters have three stages of filtration:

— preliminary filter of galvanized multilayer notched net (washable)

— HEPA H13 GOST R EN 1822 fine filter (accumulative, non-regenerable)

— activated carbon filter (non-regenerable)

Fumes and aerosols are captured by BEA extraction arms, which are to be ordered separately, depending on required reach radius and lighting option.

Intended operators

• Industrial enterprises

• Laboratories

• Engineering workshops

• Educational facilities

Rate of working recommendations

• for semiautomatic welding in an atmosphere of shielding gas – expenditure of welding wire up to 30 kg per month

• for manual arc welding – expenditure of welding wire up to 15 kg per month

For more intensive applications self-cleaning DCSC-M-5 and DCSC-M-6 are recommended.

• Compact size and light weight

• Robust metal case

• Big casters (two of which are with brakes) for uneven floors

• Light indication of cartridge critical dirtiness

• Activated carbon filter for removal of toxic gases and scents in standard trim

• Washable preliminary filter for main cartridge protection from sparks and large dust particles

• 230 and 400 V variants

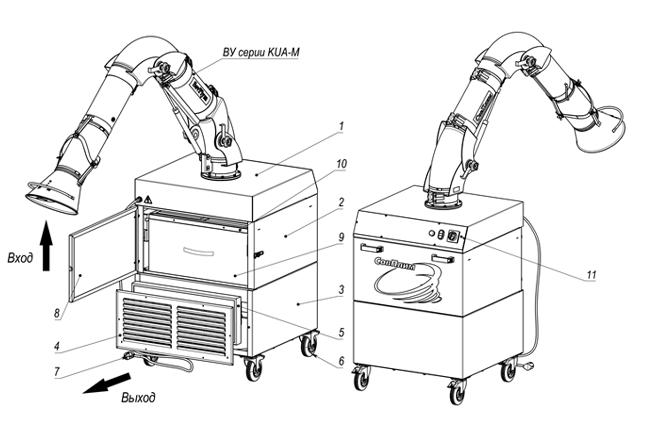

Composition and operation principle

2. filter module frame;

3. fan frame;

4. outlet grill;

5. carbon filter;

6. rotating caster with brake;

8. door;

9. HEPA (МК-005) cartridge;

10. preliminary filter;

11. control panel.

1. Air-dust flow is sucked through extraction arm be a fan. Contaminated contours protective screen and preliminary filter (item 10), which evenly distributes the flow and protects cartridge (item 9) by capturing large particles.

Air goes through cartridge filtering material, leaving small contaminants on its surface. Cleaned air then leaves filter through through outlet grill.

2. With time dust layer on cartridge surface grows and resistance to airflow get bigger, which indicated necessity of cartridge replacement.

IMPORTANT! Extraction arm is to be ordered separately.

| Parameter or characteristic | ||

|---|---|---|

| Model | ||

| Part number | ||

| Max airflow, cmh | ||

| Built-in fan power, kW | ||

| Voltage, V (Frequency, Hz) | ||

| Control panel power, W | ||

| Cartridge displacement | ||

| Cartridge model | ||

| Filtration class according to GOST R EN 1822-1 | ||

| Final filtration stage | ||

| Noise level not more than, dB | ||

| Dimensions without handle, mm | ||

| Air inlet diameter, mm | ||

| Quantity of air inlets | ||

| Weight not more than, kg (without extraction arm) | ||

| Control panel protection class according to GOST 14254 (IEC 60529:2013) | ||

| Picture | Article № | Model | Description |

|---|---|---|---|

| FF-MFC | Preliminary filter. Made of galvanized multilayer notched net (washable). |

|

| 134024 | МК-005 | Main filter. Air fine filtration H13 (GOST R EN 1822). Filter surface area 25 m². Material – fiberglass. |

| 134035 | CF-MFC | Carbon filter. Depending on workload, needs to be replaces 1-2 times a year. |

Usually used with

Contacts

Arrisa Avenue, Unit #15, Office No. 303, 3rd Floor, Kolte Patil Downtown, Kharadi, Pune-411014, India