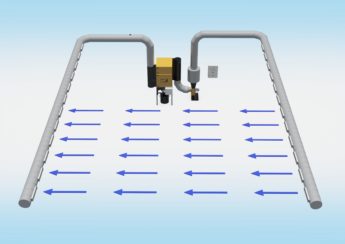

The Push-Pull system is a technical solution based on the principle of maintaining organized air circulation in individual areas or throughout the workshop space. The system provides forced displacement of the welding cloud by directed jets with the aim of capturing, filtering, and returning the cleaned air to the room using a specially designed and tuned filter-ventilation system.

Push-Pull systems prevent the accumulation of welding fumes, as well as reduce the background concentration of harmful substances in the total production space.

Push-Pull systems are always an individual solution, taking into account the features of the production process, the arrangement of equipment and products, as well as the construction parameters of the room in which this process takes place.

When developing the Push-Pull systems, the physical property of welding aerosols to ascend and hover at a height of 4–6 meters was taken into account, forming a cloud that can be clearly seen visually.

To eliminate the welding cloud, a filter ventilation system has been developed, equipped with two branches of ducts located on opposite walls of the room at the height of cloud formation. To create a layered airflow, special pressure grilles of the BG-1300 (PUSH) model are installed on one branch of the air ducts, and exhaust grilles of the SG-1300 (PULL) model on the opposite branch. Between the Push and Pull branches of the system, a self-cleaning modular filter of the DCSC-S series is installed complete with a fan in a noise-attenuating casing and a silencer. If additional air purification from gases and odours is required, a special filter for gas components of the GC type is installed after the self-cleaning filter.

Depending on the required airflow and the characteristics of the premises, the Push-Pull systems can have a different configuration and are equipped with filters of different capacities. The system is controlled automatically using a special panel- CONT-PP.

Filter performance, length of ducts, number of gratings and airflow through them are calculated by SovPlym Ltd specialists based on the volume of the room, the distance between the walls, the type of welding, the type and consumption of welding electrodes, the grade of the metals being welded, and a number of other parameters.

| Model | Description |

|---|---|

| sOL adapter | Adapter for connection of rectangular-shaped outlets of VMK, VMA, VM-FS, TEF fans to a hard or flexible round-shaped air duct. OL adapter is also required for mounting the silencer of GTK series or similar. |

Contacts

Arrisa Avenue, Unit #15, Office No. 303, 3rd Floor, Kolte Patil Downtown, Kharadi, Pune-411014, India