SFM series filters are a cost-effective way to solve various aspiration tasks. They are single-block semi-automatic non-continuous pocket filters with a filtration surface area of 6 to 45m2 and mechanical stirring of filter elements. The fan should be disconnected periodically to regenerate the filter. The filter is used to clean air or gases from various types of dry, loose, and non-sticky dust. The SFM filters are suitable both for indoor and outdoor installations.

Applications

• Aspiration of silo and bunker loading/unloading

• Aspiration of process and associated equipment

• Aspiration of pouring sites, conveyor belts, conveyors, and elevators

• Aspiration of crushers, mills, screens, refrigerators, mixers, and dispensers

• Aspiration of shot blasting and surface treatment

Industries

• Chemical

• Metallurgical

• Metal working

• Mining

• Food

• Pharmaceutical

• Machine building

• Production of construction materials

• Cement production

• Other industries

Limitations

• No structural protection against explosion.

• Not intended for continuous operation.

• Not intended for the following types of dust.

— for smoldering and self-igniting dust.

— for fibrous dust.

— for sticky dust.

— for dust with moisture.

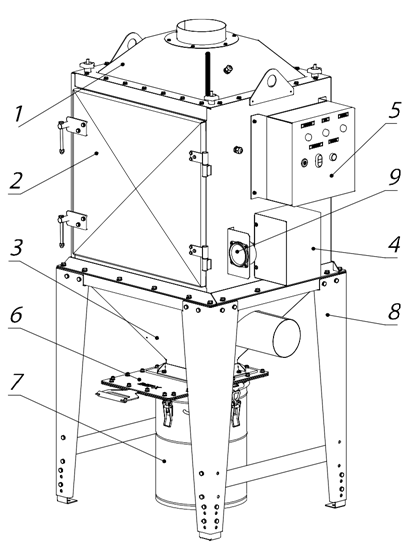

| SFM Filter Design SFM filters of series production consist of a body with a conical dust collector (see the figure on the right) mounted on supports, a dust collection container with a manual cut-off butterfly valve, and a regeneration system. Filters are equipped with a regeneration system by mechanical stirring of filter elements. Possible sizes of filters, relevant filtration areas, and rated capacities are shown in the table below. Construction |

|

| Filter Elements Filter elements of SFM filters are flat, smooth woven pockets sewn in the upper part into one piece. A metal mesh frame stretched on a rectangular metal bar chassis is inserted inside each pocket. |

|

Type of filter elements used in SFM series filters

| Designation | Filter type | Pocket material | |

|---|---|---|---|

| PF-P6-SFM | SFM 06 | Polymeric ester | |

| PF-P13-SFM | SFM 13 | Polymeric ester | |

| PF-P23-SFM | SFM 23 | Polymeric ester | |

| PF-P30-SFM | SFM 30 | Polymeric ester | |

| PF-P45-SFM | SFM 45 | Polymeric ester | |

| PF-C6-SFM | SFM 06 | Antistatic polyester | |

| PF-C13-SFM | SFM 13 | Antistatic polyester | |

| PF-C23-SFM | SFM 23 | Antistatic polyester | |

| PF-C30-SFM | SFM 30 | Antistatic polyester | |

| PF-C45-SFM | SFM 45 | Antistatic polyester |

Special features of SFM filter regeneration

Since SFM series filters are regenerated by mechanical stirring, they need to be stopped periodically. Their operating cycle is about 2 hours, stirring is 90seconds (factory settings, adjustable parameter). During regeneration, airflow through the filter should be stopped. This can be done by installing a special control unit on the filter to stop the fan before starting the stirring motor, by manually pressing a regeneration activation button, and starting up the stirring motor after its run-out. At the end of regeneration, the control unit automatically stops the stirring and starts up the fan until the next pressing of the regeneration activation button. A standard filter is not equipped with a fan, therefore the control unit only provides a manual start and automatic shutdown of the stirring motor.

Design features

• Easy assembly and installation

• Flat filter pockets for heavy applications

• Mechanical filter cleaning system

• Two-stage filtration with additional module (option)